If you’ve flown helicopters long enough, you’ve done that short hop after maintenance where you’re tuned into every sound and vibration. That was the plan in Fresno on the morning of October 1, 2022: a quick operational check after inspections on a Bell 206B, registration N284CA. Conditions were benign—light winds, clear skies, Class C airspace around Fresno Yosemite (KFAT). Then a loud crack echoed through the cabin, the helicopter yawed hard to the right, and the rest of the flight became an exercise in energy management and damage limitation.

Who Was Flying, and What They Brought to the Table

The pilot was no rookie. At 46, he held a commercial certificate with helicopter instrument privileges and instructor ratings for both helicopter and instrument helicopter. He had logged 3,811 total flight hours, with 2,119 hours in the Bell 206 series—real time in type, not just a few hours to check the box. He was current in the aircraft and held a current second-class medical. That level of experience matters here because what happened next demanded precise, practiced inputs under pressure.

The Mission and the Moments Before the Failure

This was a Part 91 “other work use” flight—essentially that post-maintenance hop to validate recent inspections. A mechanic rode along in the left seat to help verify items. They wrapped up their checks and started the turn back toward the airport. Everything looked and felt normal until it didn’t. Both occupants heard a loud “crack/pop,” and the helicopter immediately began an uncommanded right yaw. Anyone who’s trained tail-rotor-failure profiles knows that sound and that sensation: the tail is no longer doing its job. The pilot called it what it was—tail rotor failure—and entered autorotation toward an open area ahead: the front yard of a residence.

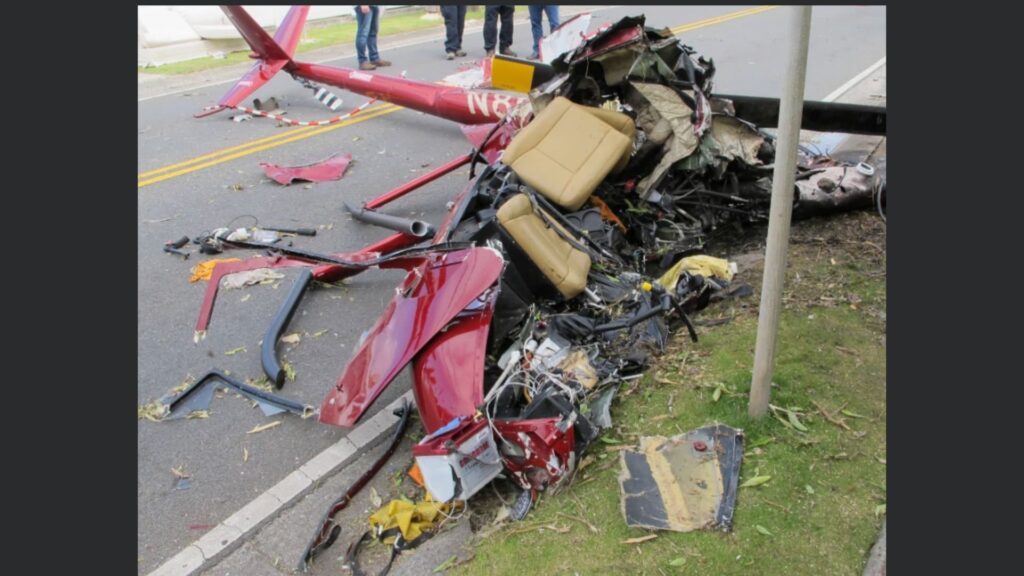

The Autorotation and Impact

Autorotation in a 206 is not exotic, but doing it for real with partial directional control is a handful. The crew had maybe seconds to pick a spot and commit. On short final, the machine clipped a tree, hit hard, and rolled onto its left side. The landing gear skids did their best, but the helicopter still took substantial damage. Both the pilot and passenger sustained serious injuries. There was no post-impact fire. The coordinates put the touchdown in a neighborhood not far south of the airport—proof that quick, decisive action got them as close as possible to a survivable landing area.

What Broke: A Disbond in the No. 4 Tail Rotor Drive Shaft

Post-accident teardown keyed in on the tail rotor drive system—and specifically the No. 4 segmented drive shaft. The forward splined adapter had disbonded from the aluminum shaft tube. When that adhesive bond let go, the adapter kept spinning under power while the tube slowed, severing effective drive to the tail rotor gearbox. That’s your loss of anti-torque right there. Heat and re-solidified adhesive on the fracture surfaces told a story of the adapter turning inside the tube after the bond failed, which also erased some forensic clues about why the bond let go in the first place. The lab also measured a tapered thin wall on the splined adapter that did not meet thickness specs, though investigators stopped short of calling that the sole cause. On page 4, the photo of the separated adapter (Figure 1) shows exactly where the system parted ways.

Maintenance, ASBs, and Proof-Load Testing—Did the System Catch This?

Bell had already been chasing this failure mode. An Alert Service Bulletin (ASB) for 206-series helicopters—No. 206-20-139—called for an initial and recurring visual inspection of the bond line, indexing marks to detect rotation, and a proof-load test of the bonded adapter using a specific tool. Transport Canada turned that into AD CF-2022-33, and the FAA followed with AD 2023-06-05, locking parts of the ASB into regulatory requirements. The operator of N284CA had been on it: they’d done the proof-load routine four times since the ASB came out and most recently about 77.7 flight hours before the accident, with no anomalies observed. Their bonded-shaft tool dimensions checked out within spec, and there was no evidence they over-torqued anything during testing. In other words, the maintenance program was playing by the rules and still didn’t catch an impending disbond.

A Wider Lens: This Wasn’t the First Disbond

From 1986 to 2023, Bell counted 16 known in-service disbonds on 206A/206B segmented tail rotor drive shafts with bonded adapters, including this accident. Eleven of those could not be traced to a specific root cause because the post-failure damage obscured the original trigger—exactly what happened here. Of the remaining five, three involved re-using a shaft after a known tail rotor sudden stoppage event, one involved adhesive damage from media blasting, and one traced back to inadequate adhesive during manufacture. The shafts aren’t life-limited and aren’t required to be tracked from the factory, so the age and service time of this particular No. 4 shaft couldn’t be pinned down—another variable that complicates trend monitoring.

Weather, Environment, and Distractions

Weather wasn’t part of the equation. The 09:53 local observation at KFAT—just two minutes before the accident time—showed VMC, 10 miles visibility, clear skies, winds about 120° at five knots, and a standard altimeter setting. This was a clean day for a check flight—no turbulence, no precip, nothing to divide attention. That matters because it puts the spotlight directly on the mechanical failure and the crew’s response, not extraneous factors.

Probable Cause—Straightforward, but Not Simple

The NTSB called it plainly: the disbond of a tail rotor drive shaft splined adapter resulted in a loss of tail rotor drive and the subsequent hard landing. That’s as direct as these conclusions get. Underneath that line is a larger conversation about detection intervals and whether the then-specified proof-load cadence (initial within 75 hours/3 months, then every 300 hours/12 months) is tight enough to catch bonds that are already headed south. Investigators noted that the accident occurred despite compliance and may indicate the interval is not always adequate to discover an impending adapter failure.

Safety Takeaways—What Pilots and Maintainers Can Put to Work

First, if you fly a 206-series—or any platform using bonded tail rotor drive adapters—treat tail rotor anomalies with a zero-delay mindset. When yaw starts to run away, the window to convert energy and pick a survivable spot is brutally short. Practice matters. The pilot’s experience in type showed up in the outcome; despite serious injuries and substantial damage, both occupants survived a failure that offers very little margin.

Second, if you’re on the maintenance side, be meticulous with ASB/AD compliance and documentation. Index marks on bonded adapters are there to spot subtle rotation before it becomes a disbond. Proof-load testing is only as good as the tooling and the technique—verify tool dimensions, torque procedures, and restraint methods every time. This operator did those things correctly; that’s important to recognize, because it suggests we may need to think beyond the letter of the ASB when operating in higher-risk profiles, like low-altitude work or densely populated areas.

Third, consider inspection strategy. Visual inspections and proof-loads are snapshots. If your operation racks up flight hours quickly or does missions where tail rotor reliability is mission-critical, talk with your IA, your DOM, and—if you’re a larger operator—your OEM rep about whether a shorter proof-load interval or additional NDT makes sense for your risk picture. The NTSB’s summary of prior disbonds shows multiple pathways to the same failure mode, including damage from past events and manufacturing variances. That’s not a reason to panic; it’s a reason to be systematic.

Fourth, treat post-maintenance flights like test cards. Pick conservative altitudes and corridors with multiple forced-landing options. Brief abort points and decision gates. A maintenance check is not the time to be down low or over the worst terrain. The crew here aimed for the best available spot, but the environment—trees, yards, and houses—left very little room. Build a bubble of options before you need them.

Closing Thoughts

N284CA’s accident in Fresno was the kind of mechanical surprise we all train for but hope never to see. A splined adapter disbonded, the tail rotor lost drive, and the pilot fought the yaw, managed the rotor, and put the machine down as best he could in a tight neighborhood. The bigger lesson lives in that intersection between disciplined maintenance, realistic assumptions about inspection interval limits, and crew readiness for low-probability high-consequence failures. None of us gets to choose when that loud “crack” shows up—but we can choose how prepared we are when it does.

5 Comments

Hoover, excellent analysis.

Points 1 and 4 while applicable to rotor folks also can apply to all test flights. Loss of tail rotor control is train, train item. Pilot did well. Great analysis and comments

For such critical parts, isn’t there a better way of connecting them? Would a retrofit kit be prohibitively expensive? I have just a little rotorcraft time, but would be spooked flying a craft with a “bonded” critical connection

Great comment, that’s the first thing that came to my mind. Why in hell would such a critical component rely on “bonding “ process

This analysis shows how much knowledge and understanding of flight dynamics Hoover has. Much of this went over my head, thanks to all the acronyms, but it was very impressive.