This one was a classic ag-turn accident with a modern data trail behind it. On July 22, 2024, Air Tractor AT-602 N602WR went down near Oxford, Indiana while spraying two fields under Part 137. The airplane had just finished a west-to-east trim pass along the south edge of the northern field when the pilot climbed left, likely setting up to work the north side. Seconds later the airplane entered an aerodynamic stall/spin at low altitude, rolled inverted, and impacted a soybean field about a half mile east of the target area. There was no forward scuffing, no debris path across the crop—just an inverted, nose-low impact consistent with a stall/spin from a steep, low-altitude turn.

Pilot and Aircraft

The pilot was 35 and flew professionally. He held a commercial pilot certificate for single-engine land, and he operated as an occupational pilot. Investigators estimated 3,000 total hours; logbooks weren’t available, so hours in type couldn’t be confirmed. He did not hold an instrument rating or instructor privileges and was flying on a second-class medical issued about a month prior, with waivers/limitations noted. The aircraft was a 2010 Air Tractor AT-602 on a restricted category certificate, powered by a Pratt & Whitney Canada PT6A-65AG rated at 1,300 shaft horsepower. Four days before the accident, the airplane had a 100-hour inspection; records showed no unresolved discrepancies. Airframe time was about 3,887.6 hours, and the airplane was operating with a SATLOC GPS spray system. An ELT was not installed, which is common in some restricted-category ag operations but still worth thinking about for post-impact survivability and location.

The Mission and the Turn

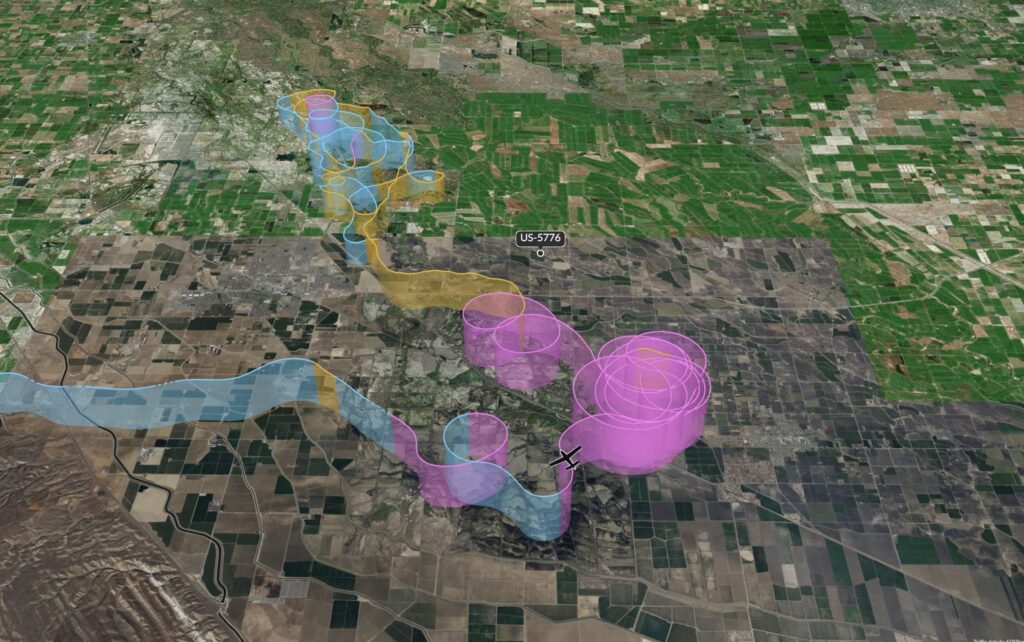

The hop started from the operator’s private strip at 17:41 local with full fuel and the hopper loaded. The pilot sprayed one field and shifted to the next, working the boundary lines (trim passes) before settling into the main pattern. On the south edge of the northern field, the GPS track showed a clean trim run to the east. The final recorded point sat just southwest of where the wreckage would be found. From there, the track and the wreckage told the same story: a climbing, tightening left turn, full flaps, and not enough margin. The AT-602 impacted inverted with no signs of forward travel through the crop, indicating the wing quit flying and the airplane departed controlled flight right there over the beans.

What the Wreckage Said

Impact marks and deformation matched an inverted, nose-low arrival on a heading of roughly 137 degrees. Both wing leading edges and upper skins were crushed downward relative to the upright fuselage. Flight-control continuity was established through impact damage, and there were no preimpact system failures noted. Investigators found the flap actuator extended to a position correlating to full flaps—about 28 degrees. The engine showed signs of power at impact, and the propeller blades displayed the classic bend and twist progression you get when the prop is producing thrust right up to the ground. A small post-impact fire started in the aft engine compartment and was put out quickly. Everything you want to see to rule out the “machine” points to a healthy airframe and engine right until airflow over the wing disappeared.

The Data (and the Lack of It)

Two pieces of tech mattered here. First, the SATLOC GPS in the spray system recorded the flight path and spray events. That data confirmed the pattern, the trim pass, and the approximate setup for the next turn. Second, the engine’s FAST (full-flight data acquisition, storage, and transmission) box, which could have given a richer picture of engine parameters and timing, had stopped recording new data back in 2019 because its memory was full. It offered nothing on the accident flight. This didn’t change the big picture, but it’s a reminder that if you rely on onboard recorders for maintenance or post-event insight, verify they’re actually logging.

Weather and Environment

Conditions were visual with 10 miles of visibility and clear skies. Winds were light westerly at around four knots, temperature 27°C, dew point 16°C, altimeter 29.96. This was a good-weather day with no turbulence reported or forecast at the site. In other words, the environment didn’t force the pilot’s hand—this was about energy management and configuration in a low-level maneuver.

Configuration and the Edge of the Envelope

The AT-602’s flight manual offers very specific guidance on flap use in turns: small deflections—five to eight degrees—as a turning aid. The usual technique is to pull up and bank with flaps retracted, then briefly “touch” the flap switch as you’re wrapping back into the field, ease off a bit of back-pressure as the flaps nudge the nose up, and retract as you roll out on the next pass. What investigators found on N602WR wasn’t a nudge; it was full flaps at 28 degrees. Full flaps lower stall speed in a straight-and-level, 1G world, but in a steep, loaded-up ag turn they can do the opposite of what you want by stacking drag on top of increased wing loading. Bank angle drives stall speed up; add a heavy pull and a draggy flap setting, and your margin over the wing’s critical angle shrinks to a sliver. The probable cause cited the exceedance of critical angle of attack and failure to maintain adequate airspeed while maneuvering, with excessive flap extension as a contributing factor.

Human Factors

The autopsy identified significant coronary artery disease—about 75% narrowing in a proximal LAD segment—and an enlarged heart with right ventricular dilation and mild LV hypertrophy. There was no toxicology issue and no direct evidence of an acute cardiac event. The NTSB’s analysis acknowledged the increased risk for a sudden arrhythmia or chest pain but also noted that such events often leave no definitive autopsy signature. Could a momentary distraction, discomfort, or subtle physiologic “blip” have nudged attention away from airspeed and bank? It’s possible. But even without a medical trigger, the operational picture fits: a quick setup turn at low altitude, full flaps, and the unforgiving math of angle of attack. For us as operators, this is a reminder to manage personal risk as actively as aircraft risk. Fitness and surveillance matter in high-demand roles like ag flying.

Lessons I’d Take to the Field

First, flap discipline. In ag work, flaps are tools, not crutches. Use the manufacturer’s “tap, don’t park” technique: small, momentary deflections to help the turn, followed by a prompt retraction as you line up for the next pass. Lock in a habit pattern here so that when workload spikes—trees, obstacles, changing spray width—you don’t default to excessive flap angles.

Second, angle-of-attack awareness at low level. In a pull-up and turn, your wing sees G, not just indicated airspeed. As bank increases, so does stall speed, and that rise is non-linear. The only universal fix is to unload first—reduce AOA—before anything else. If you feel the buffet or see the cues, relax the back-pressure first and buy the wing some airflow. Don’t try to “power through” a stall warning in a steep, flap-down turn; drag is already stealing your energy.

Third, keep the data alive. The engine FAST box being full since 2019 didn’t cause this accident, but it denied everyone—including the operator—useful trend and event data. In ag fleets, where airplanes fly hard during short windows, verifying that recorders are logging can pay dividends for maintenance planning and post-event coaching.

Fourth, personal health is part of preflight. Especially in single-pilot, low-level work, minor medical issues can become major distractions. Build a culture—at the operator and pilot level—where speaking up about symptoms and seeking follow-up isn’t seen as weakness. The pilot’s cardiovascular status may or may not have been relevant in the moment, but it certainly increased risk exposure for high-workload missions.

Closing Thoughts

When you strip away the mystery, the Oxford accident looked like many we’ve seen in ag flying: a good-weather day, a capable machine making routine passes, and a turn that got too steep and too draggy with too little altitude to spare. Full flaps at 28 degrees were incompatible with the low-level, high-G maneuver the pilot was trying to make. The wing quit, the airplane rolled through, and there was no room to recover. The machine talked—bent metal, twisted blades, flap position—and the data did what it could. The lesson is crisp: treat flaps as a brief assist, not a set-and-forget, and guard your AOA like the mission depends on it—because it does.

3 Comments

Would have been to know if the pilot was wearing a helmet and could that have helped him survive.

Very well written report with great lessons learned.

Lack of airflow over the wings will ruin your day unless you’re at the gate. AOA matters. Ag pilots are a special breed to operate at that point in the flight envelope day after day. Not much margin for error.